In various industries such as those for cutting sheet metal parts, laser technology is one of the most used in the processes of the industrial sector, mainly due to its precision and speed. Next, we will explain how a laser cutter works, advantages and industrial applications of laser cutting machines.

As a first point, you should know that laser cutting is a manufacturing process that uses a small, highly focused beam to cut and engrave designs, patterns, and shapes on a variety of materials. This manufacturing process is very suitable for certain materials such as wood, glass, paper, plastic, cardboard and metal.

How does laser cutting work?

Laser cutting is a technique used to separate parts using thermal energy.

During the cutting process, the laser beam focuses light on a point on the surface of the workpiece, raising its temperature until it melts or evaporates. Once the laser beam has crossed the surface, the cutting process begins, redirecting the laser beam to a certain point according to the chosen geometry, until the material is completely separated.

Once the cutting process is finished, it is carried out with professional and high-tech machinery, and pressurized gas (oxygen, nitrogen or carbon dioxide) is used to extract the resulting material.

What parts does a laser cutter have?

These machines are made up of various parts:

laser resonator

- The beam is generated by a resonator, which is a closed glass tube with two mirrors facing each other. The tube is filled with carbon dioxide and other gases such as hydrogen, nitrogen, or helium. When the machine is turned on, an electrical discharge occurs and these gases turn into light.

Cutting head

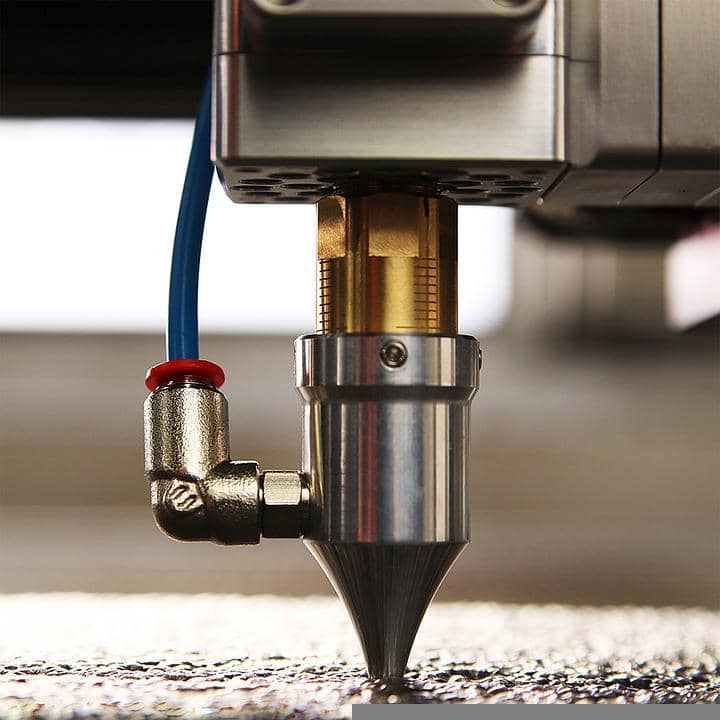

- The light is reflected by different mirrors so that the laser reaches the cutting head. Once the beam gets here, it passes through a curved lens that magnifies and focuses it to a point (similar to using a magnifying glass to light a fire with sunlight), allowing it to cut and record. Often the cutting head is associated with a mechanical belt or chain system, allowing precise movement within an area.

cutting distance

- It always maintains a certain distance between the material and the nozzle from which the laser is fired. This distance is very important because it determines the focus. Generally speaking, changing this approach will affect the quality of the laser cut.

The beam diameter of the laser cutting machine is usually 0.1mm and 0.3mm, and the power is about 1-3kW. This power is adjusted according to the material and its thickness. To cut reflective materials such as aluminum, a laser cutter with a power of about 6 kW may be required. This is because metals have high thermal conductivity and the ability to reflect light, so the applied heat (and thus energy) must be very high to overcome these obstacles.

Advantages of using a laser cutter

These machines consist of a lot of energy, in this case light, which raises the temperature of the metal, causing it to melt and begin to evaporate, which is when the direction of the laser path begins, creating the cut. They are the most complex tools for cutting metal because they can be programmed to precisely cut perfect and complex shapes.

1. High precision

Among the main reasons for using laser technology in the processes of cutting sheet metal parts in the industrial sector, the following stand out:

It allows cutting of different geometric shapes, whether they are irregular, fine or with complex contours. It is suitable for pre-cutting or trimming excess material.

2. Versatility

It can be used for the separation of different organic and inorganic materials, including metal sheets or materials that allow the construction of parts with different geometries of steel, stainless steel or aluminum sheets. No other technology can cut as many different types of organic and inorganic materials as the laser cutter can.

3. Agility

The laser cutting process does not require cutting dies for the manufacture of parts and, furthermore, it allows silhouette adjustments to be made.

4. Efficiency

After using the laser, it is not necessary to carry out a subsequent processing of the piece such as sealing or sanding, which means that it saves time in the manufacturing process. It even seals factory edges such as synthetics or carpet so they don't fray. This saves post-processing procedures such as mechanical sealing or sanding, depending on the type of material being processed.

5. No tool wear

- Laser cutting machines are not subject to wear, since the head does not have tools that lose their properties with use. This saves money on ongoing work operations.

Do you know the difference between laser cutting and others found on the market? check out this blog: Plasma cutting vs laser cutting

What materials can be cut with the laser?

Currently, laser technology, especially its cutting process, is a working method that is frequently used to cut various materials. The high precision, speed and versatility of lasers are great advantages. Here we explain how laser cutting works and what materials it can be used for.

Laser technology allows the processing of a wide variety of plastic, textile, organic or metallic materials. Depending on the machinery used and the material of the part, it can be subjected to different processes such as cutting, engraving, marking, etc.

Laser cutting allows to process sheet metal parts and metallic materials such as:

- Stainless steel

- Steel sheets

- Aluminum

- Anodized aluminum

- Chrome

- Precious metals

- painted metal

- Brass

- Copper

- Titanium

What types of laser cutting are there?

There are 3 types or varieties of laser cutting today:

1. Burnt/Reactive:

This type of laser cutting uses oxygen as a carrier gas. Gas is injected into the cutting groove under high pressure. The substance reacts with oxygen, burns and oxidizes. This interaction produces energy, which gives the laser more power. This type of laser cutting is commonly used on metal.

2. Fusion:

An inert gas such as nitrogen helps the laser expel molten material from the cutting area. This means that the energy required to make the cut is much less. This grade is used for metals in general

3. Sublimation:

- A high-intensity laser vaporizes (sublimates) the material, allowing thinner plates to be cut without the need for carrier gas. This type of laser cutting is used for non-metallic materials.

In Perez Precision Works, we specialize in the process of Laser cut of metals. We have the latest technology for both laser cutting as well as for the prototyping of even longer chains that can be used in industrial sectors.

Perez Precision Works, specialized in providing solutions to the industry, we have CO2 and Fiber laser cutting machines that allow us to modify executable programs without the need to produce a tool.

Contact us to learn more about Laser cut.