It is compatible with a wide range of materials, such as stainless steel, aluminum, copper, plastics and many others. Its exceptional versatility not only encompasses the diversity of materials, but also allows it to tackle diverse projects with the highest precision and efficiency, ensuring outstanding results.

It guarantees exceptional millimeter precision in cuts and shapes, backed by precise technological control. This control not only minimizes thermal damage, but also ensures impeccable finishes on each piece.

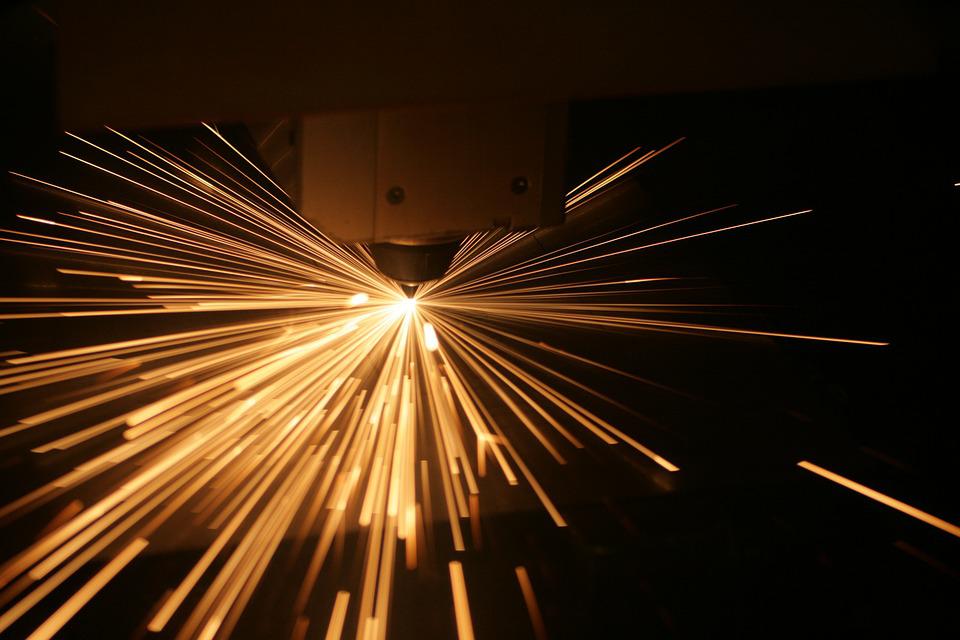

Laser cutting is a smart choice because of its microscopic precision, allowing complex shapes to be created with exceptional detail. It offers speed and efficiency, streamlining projects in a 95% and reducing deadlines.

Its versatility ranges from stainless steel to various materials, optimizing results and raising quality standards.

It is noted for its microscopic precision and the ability to handle a wide variety of intricate shapes and designs with absolute meticulousness.

Unlike other methods, there is no direct physical contact with the part, effectively minimizing distortion and potential associated thermal damage. This, in turn, results in clean, detailed cuts that reflect exceptional quality.