Have you ever wondered how precise metal shapes are achieved in modern industry? The answer lies in the CNC bending machine. This revolutionary machine transforms metal with millimetric accuracy, optimizing the production and quality of your production.

If you are thinking about integrating a CNC bending machine into your business or you already have one and want to learn more about its use, you are in the right place! Keep reading and be amazed by the possibilities that this incredible technology offers you.

Do you know what a CNC bender is?

A CNC bending machine is a computer numerical control machine, as its acronym indicates. This tool works automatically through a programmed control system, which allows for the efficient and precise processing and production of complex parts.

CNC machines generally need to be controlled by a computer using numerical coordinates. There are various types of bending machines on the market, the most common of which are those powered by electric motors. There are also bending machines that operate using hydraulic systems, manual bending machines, and of course, CNC machines.

If you want to know more about our services and how we can help you integrate CNC technology into your processes, click here!

Types of benders

As indicated above, there are various types of bending machines on the market. Next, we will list the most common benders and talk about their characteristics:

to. Manual benders:

It is one of the most commonly used types of bending machines, especially in workshops that are not at an industrial level, since it does not require more science for its implementation, they are very practical when used, but they do require that the person who works with it apply the greatest force manually when attempting to fold a sheet.

b. Electric benders:

Electric benders are simple but flexible and reliable. These types of machines will be the machines of the future, since they integrate care for the environment with productivity, precision and flexibility, as well as generating low energy consumption and less maintenance as they do not include hydraulic components.

c. Hydraulic benders:

They have a similar job to electric benders, the difference is that they use a hydraulic pump that provides the inertia required to activate the piston. These machines compete with the quality of CNC bending machines, as they can reach too high tonnages by means of the lever effect and their results are very exact.

d. CNC bending machines:

They are the most innovative bending machines in the metal-mechanic industry, since their operation is carried out by means of numerical control and their results are the most precise, they have higher performance and their finishes can be achieved even in deep sheet diameters.

CNC bending machine operation

CNC bending machines are the most intelligent on the market, since they are fully automated machines that have an advanced computer system, where they use high-strength parts that are powered by electric motors.

Keep in mind that any of the electric motor CNC benders allow us to bend or bend tubes with simple or complex shapes with excellent quality, later we will talk about the advantages of using CNC benders.

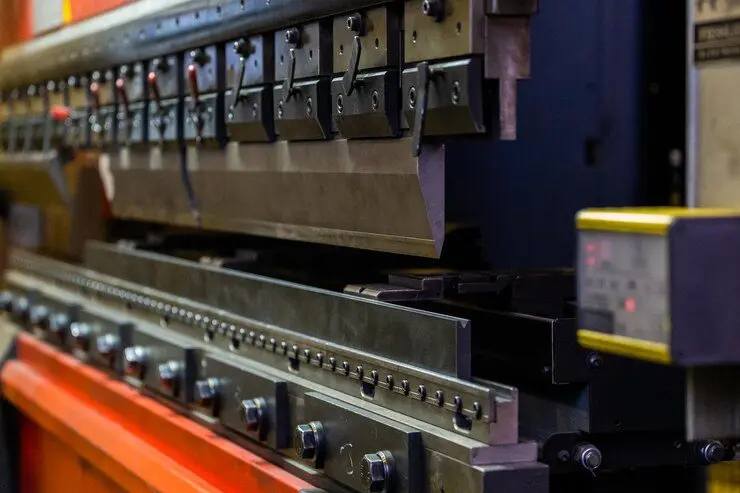

Roughly speaking, the operation of the CNC bending machine consists of changing the shape of a metal sheet through a bending that is achieved with certain determined angles oscillating 90 degrees, for this we need a male punch, that is, in the form of v and a v-shaped die.

The most detailed procedure of the CNC bending machine is that pressure is applied between two dies in a specialized press where, through the incorporation of pressure with the punch, the die and observing the angles, the metal plate is bent, a Once this objective is achieved, the external fibers of the metal are put under tension without producing significant changes in the thickness of the metal.

Basically, a CNC bending machine is a top piston press which works with two parallel motion working hydraulic cylinders which form a vertical pressure to drive the mold on the bending beam, computerized numerical control mainly controls the bending process and positioning. of the hydraulic cylinder when the machine is running.

The CNC bending machine can achieve more specific bends through the position of the angles, from very acute to very obtuse angles, perfect for the production of all kinds of furniture such as cabinets, special pieces, or simple bending of metal plates.

Advantages of using a CNC bender

- CNC bending machines make advanced bends

- They are flexible and reliable machine to use.

- They are the best machines on the market, as they use state-of-the-art technology.

- They produce bends of the highest quality.

- It boasts high working speeds, thus achieving greater production of sheet bending of various materials.

- CNC benders have higher bending force compared to manual benders.

- They are machines that provide a strong welded structure.

- They have longer cylinder stroke

- Most CNC bending machines use a 4-point guide system on the ram which gives more reliability.

Having so many qualities, it guarantees better precision and durability in the up and down movements of the bender.

Recommendations when using a CNC bending machine

Before starting to operate a CNC bending machine, it is essential to follow a series of recommendations that guarantee both the safety of the operator and the efficiency of the process. Below, we offer you some key tips to ensure optimal use of this powerful tool:

- Make sure the operator is trained: The person operating the CNC bending machine must have adequate professional training to operate the machine accurately and safely.

- Personal protective equipment: Verify that the operator uses the appropriate personal protective equipment to minimize risks during contact with the machine.

- Pre-inspection: Before turning on the machine, perform a thorough inspection of both the bending machine and the working environment. Make sure everything is in top condition.

- Preparation of the sheet: Make sure that the sheet to be bent is correctly positioned and free of obstructions to facilitate its movement during the process, ensuring greater safety and precision.

- Responding to technical failures: If you detect any technical failure during the process, press the emergency button immediately. Do not continue with the process if you observe any anomaly, and wait until everything is in optimal conditions to resume the operation.

- Closing and storage: After finishing work, store the machine and the program used properly to avoid damage from external factors and ensure their preservation.

At Perez Precision Works,, We have a large inventory of machines CNC bending machines Available in Puerto Rico and 4 other countries. Learn more about our options and how we can help you optimize your production!

Ready to take the next step? Contact us for more information and personalized advice.